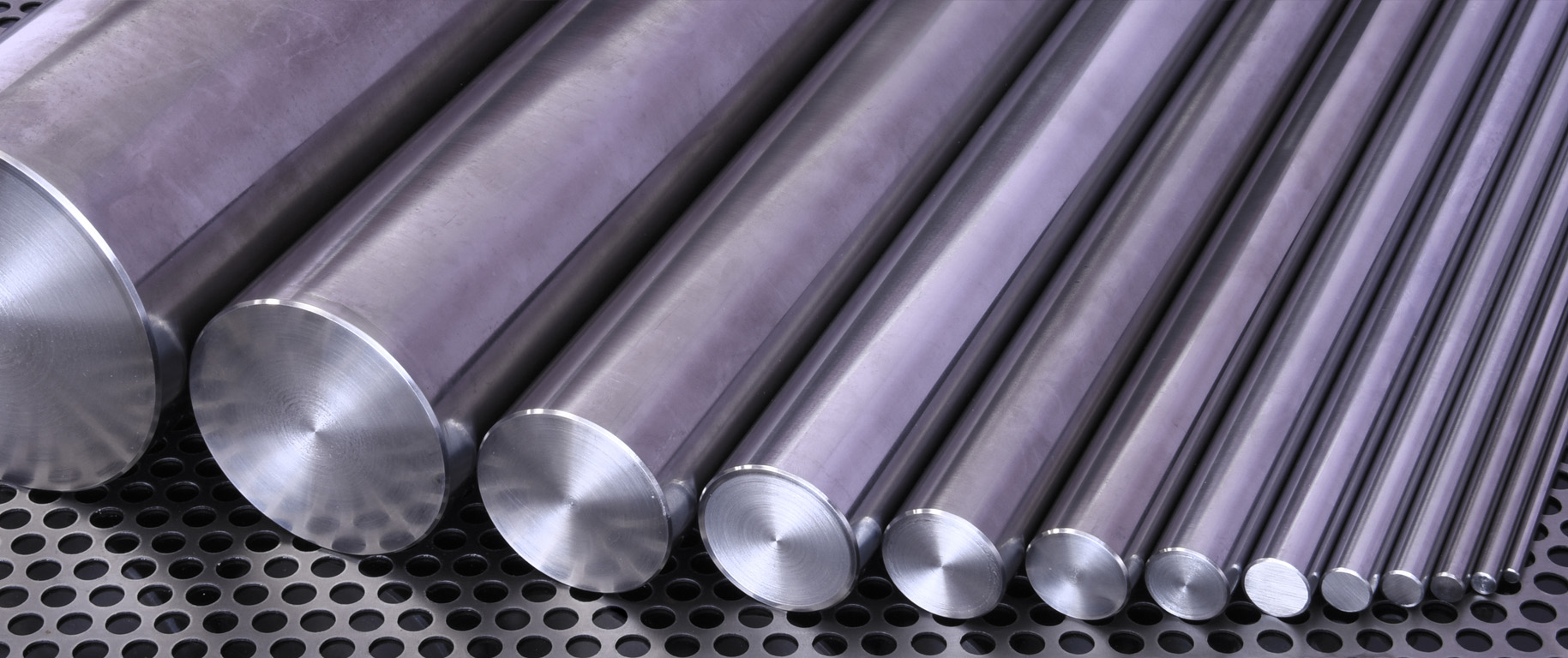

The CF53 Induction Hardened Linear Shaft also known by the code W for metric diameters and WZ for imperial diameters, is the most commonly used linear shaft that we stock. In metric sizes (W) we stock from 3mm to 100mm diameter, whilst in imperial we stock from ¼” to 3” diameter shaft.

Induction hardened linear shafts present a soft shaft core which ensures a good resilience. To the untrained eye, Linear Shafts may appear the same as other shafts, but the metallurgical differences are notable.

The manufacturing processes used to achieve the required standards, results in significant performance differences between linear shaft and other steel bars. One of these processes is induction hardening, which is a type of heat treatment where firstly the linear shafts are heated by induction heating, followed by quenching. The result of this heat treatment is it increases the hardness and brittleness of the linear shafts, which consequently requires considerable engineering experience in the cutting of the bar when breaking through this ‘induction hardened skin’ as well as subsequent machining operations, for example milled flats, key ways and planes, radial and axial drilling and tapping, and turned-down diameters.

The inner race of the linear shafts demands the highest levels of surface hardening, surface topography, taper & roundness, diameter, surface finish, material cleanliness and straightness to ensure optimum performance with minimal wear and ongoing maintenance. This is fundamental for the long life required for the application it serves.

There’s no end to the applications for the Linear shafts that we supply: from piston rods in pneumatic cylinders in machinery for a wide range of industries; for example, packaging, food, printing, instrumentation and testing; to use in press toolmaking, CNC Machinery, power transmission, and hydraulic applications.

There is no end to the applications for the linear shafts we supply

For any of your linear shaft or machining requirements, please email us or call us on +44 (0)1384 233397.

W

Precision Shafts

Material: Quenched and tempered steel (cf53/ck55) (1.1213/1.1203)

Series W

SWIPE RIGHT-LEFT TO VIEW MORE DATA

| Shaft Designation | Shaft Diameter d | Standard Length | Hardening depth Rht DIN 6773 | Standard tolerance ISO h6 | Roundness | Paralleism | Straightness | Weight |

|---|---|---|---|---|---|---|---|---|

| Type | mm | mm | mm | μm | μm t1 | μm t2 | mm/m t3 | Kg/m |

| W-3 | 3 | 1100 | 0.4 - 0.6 | 0 - 6 | 3 | 4 | 0.16 | 0.055 |

| W-4 | 4 | 2100 | 0.5 - 0.8 | 0 - 8 | 3 | 4 | 0.16 | 0.1 |

| W-5 | 5 | 3200 | 0.5 - 0.8 | 0 - 8 | 4 | 6 | 0.16 | 0.16 |

| W-6 | 6 | 6000 | 0.5 - 0.8 | 0 - 8 | 4 | 6 | 0.16 | 0.23 |

| W-8 | 8 | 6000 | 0.6 - 0.9 | 0 - 9 | 4 | 6 | 0.16 | 0.4 |

| W-10 | 10 | 6000 | 0.7 - 1.0 | 0 - 9 | 4 | 6 | 0.12 | 0.62 |

| W-12 | 12 | 6000 | 0.8 - 1.2 | 0 - 11 | 5 | 8 | 0.12 | 0.89 |

| W-13 | 13 | 6000 | 0.8 - 1.2 | 0 - 11 | 5 | 8 | 0.12 | 1.04 |

| W-14 | 14 | 6000 | 0.9 - 1.3 | 0 - 11 | 5 | 8 | 0.12 | 1.21 |

| W-15 | 15 | 6000 | 1.0 - 1.4 | 0 - 11 | 5 | 8 | 0.12 | 1.39 |

| W-16 | 16 | 6000 | 1.1 - 1.5 | 0 - 11 | 5 | 8 | 0.1 | 1.58 |

| W-18 | 18 | 6000 | 1.1 - 1.5 | 0 - 11 | 5 | 8 | 0.1 | 2 |

| W-20 | 20 | 6000 | 1.2 - 1.5 | 0 - 13 | 6 | 8 | 0.1 | 2.47 |

| W-22 | 22 | 6000 | 1.2 - 1.5 | 0 - 13 | 6 | 8 | 0.1 | 2.98 |

| W-24 | 24 | 6000 | 1.4 - 1.6 | 0 - 13 | 6 | 8 | 0.1 | 3.55 |

| W-25 | 25 | 6000 | 1.5 - 1.7 | 0 - 13 | 6 | 8 | 0.1 | 3.85 |

| W-28 | 28 | 6000 | 1.5 - 1.8 | 0 - 13 | 6 | 9 | 0.1 | 4.83 |

| W-30 | 30 | 6000 | 1.5 - 1.9 | 0 - 13 | 6 | 9 | 0.1 | 5.55 |

| W-32 | 32 | 6000 | 1.5 - 1.9 | 0 - 16 | 6 | 9 | 0.1 | 6.31 |

| W-35 | 35 | 6000 | 1.8 - 1.9 | 0 - 16 | 7 | 11 | 0.1 | 7.55 |

| W-40 | 40 | 6000 | 1.6 - 2.0 | 0 - 16 | 7 | 11 | 0.1 | 9.87 |

| W-45 | 45 | 6000 | 1.6 - 2.0 | 0 - 16 | 7 | 11 | 0.1 | 12.5 |

| W-50 | 50 | 6000 | 2.2 - 2.6 | 0 - 16 | 7 | 11 | 0.1 | 15.4 |

| W-55 | 55 | 6000 | 2.2 - 2.6 | 0 - 19 | 7 | 11 | 0.1 | 18.64 |

| W-60 | 60 | 6000 | 2.2 - 2.6 | 0 - 19 | 8 | 13 | 0.1 | 22.2 |

| W-70 | 70 | 6000 | 2.2 - 2.6 | 0 - 19 | 8 | 13 | 0.1 | 30.2 |

| W-75 | 75 | 6000 | 2.2 - 2.6 | 0 - 19 | 8 | 13 | 0.1 | 34.7 |

| W-80 | 80 | 6000 | 2.2 - 2.6 | 0 - 19 | 8 | 13 | 0.1 | 39.5 |

| W-90 | 90 | 6000 | 2.2 - 3.2 | 0 - 22 | 8 | 13 | 0.2 | 49.92 |

| W-100 | 100 | 6000 | 2.2 - 3.2 | 0 - 22 | 8 | 13 | 0.2 | 61.62 |

WZ

SWIPE RIGHT-LEFT TO VIEW MORE DATA

| Shaft Designation | Shaft Diameter d | Standard Length | Hardening depth Rht DIN 6773 | Tolerance Class "L" | Roundness | Paralleism | Straightness | Weight |

|---|---|---|---|---|---|---|---|---|

| Type | mm | Inch | Inch | Inch | Inch t1 | Inch t2 | Inch t3 | Kg/m |

| WZ 1/4 | 6.35 | 237 | 0.019 - 0.031 | -0.0005 / -0.0010 | 0.0002 | 0.0002 | 0.008 | 0.25 |

| WZ 3/8 | 9.525 | 237 | 0.027 - 0.039 | -0.0005 / -0.0010 | 0.0002 | 0.0002 | 0.008 | 0.56 |

| WZ 1/2 | 12.7 | 237 | 0.031 - 0.047 | -0.0005 / -0.0010 | 0.0002 | 0.0003 | 0.008 | 0.99 |

| WZ 5/8 | 15.875 | 237 | 0.043 - 0.059 | -0.0005 / -0.0010 | 0.0002 | 0.0003 | 0.008 | 1.55 |

| WZ 3/4 | 19.05 | 237 | 0.047 - 0.059 | -0.0005 / -0.0010 | 0.0002 | 0.0004 | 0.008 | 2.24 |

| WZ 1 | 25.4 | 237 | 0.059 - 0.066 | -0.0005 / -0.0010 | 0.0002 | 0.0004 | 0.008 | 3.97 |

| WZ 1 1/4 | 31.75 | 237 | 0.059 - 0.074 | -0.0005 / -0.0010 | 0.0003 | 0.0004 | 0.004 | 6.22 |

| WZ 1 1/2 | 38.1 | 237 | 0.062 - 0.078 | -0.0006 / -0.0011 | 0.0003 | 0.0004 | 0.004 | 8.95 |

| WZ 2 | 50.8 | 237 | 0.086 - 0.102 | -0.0005 / -0.0013 | 0.0003 | 0.0004 | 0.004 | 15.91 |

| WZ 2 1/4 | 57.15 | 237 | 0.086 - 0.102 | -0.0007 / -0.0015 | 0.0003 | 0.0005 | 0.004 | 20.13 |

| WZ 2 1/2 | 63.5 | 237 | 0.086 - 0.102 | -0.0007 / -0.0015 | 0.0003 | 0.0005 | 0.004 | 24.85 |

| WZ 3 | 76.2 | 237 | 0.086 - 0.102 | -0.0008 / -0.0017 | 0.0003 | 0.0005 | 0.004 | 35.78 |