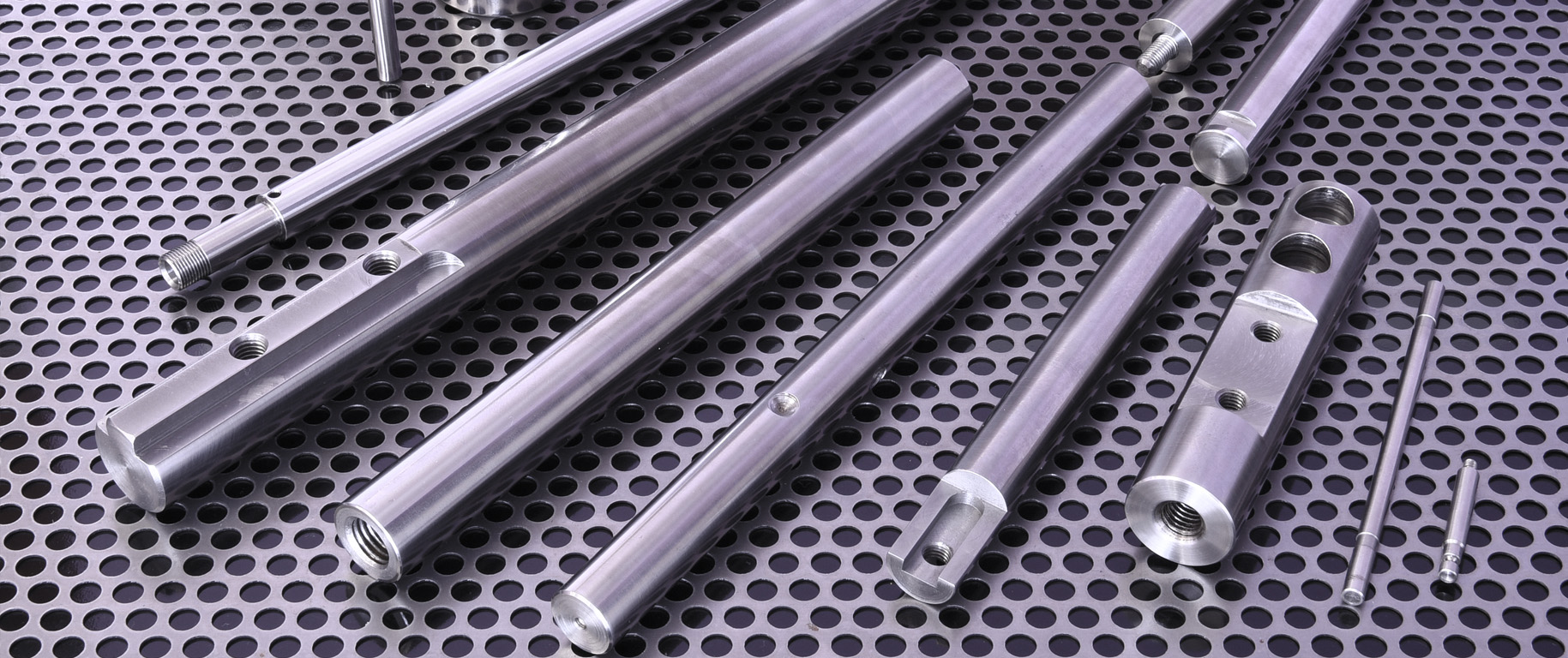

Linear shaft support rails can be implemented both vertically and horizontally and are available in a variety of different types depending on your application loading and envelope requirements. Headland Engineering provide a multitude of linear shafting services including …

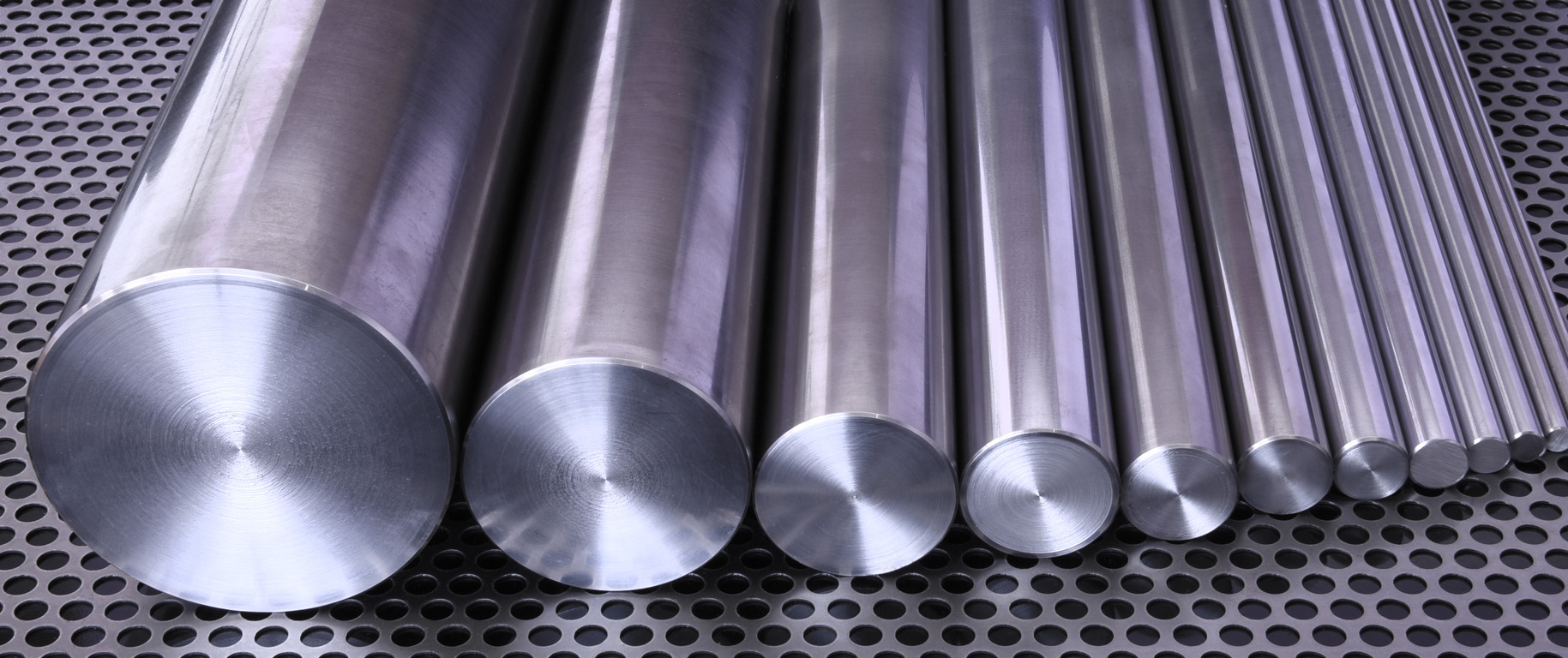

CF53 Steel

Also referred to by the code W (for metric diameters) and WZ (for imperial diameters). The most frequently used linear shaft in stock, from 3mm to 100mm diameter. In imperial we stock from ¼” to 3” diameter shaft. Presenting a soft shaft core, ensuring strong resilience – Linear Shafts may not have noticeable visible differences to other shafts, but the metallurgical differences are notable.

Read More about CF53 Steel here >> | Click here to enquire about linear shaft support rails >>

CF53-HCP – Hard Chrome Plated Steel

Fundamentally our CF53 (W) material with higher corrosion resistance due to its hard chrome plated outer layer. Headland Engineering recommend Chrome plated linear shafts for complex applications requiring high metallurgical functionality, corrosion resistance, and aesthetics. The surface of our Chrome plated linear shafts have high wear and corrosion resistance through a minimum 7µm and usually 15µm thickness micro-crack chrome plated finish. The micro-cracked chromium has a Vickers hardness of 800-1000kg/mm². This is integral to this material’s popularity and versatility.

Read More about CF53 Steel Hard Chrome Plated here >> | Click here to enquire about linear shaft support rails >>

X90 Stainless Steel Linear Shafts

Ideal for applications where maximum corrosion resistance is a high priority and the process they are subjected to during production requires prevention of internal stresses. Induction hardened linear shafts have a soft shaft core, resulting in a high resilience … The X90 linear shaft may initially appear the same as any other linear shafts, metallurgical differences are noticeable.

Read More about X90 Stainless Steel >> | Click here to enquire about linear shaft support rails >>

X46 – Stainless Steel Linear Shafts

Approximately 17-19% Chromium content, giving the shafts their High corrosive resistance. The 0.9-1.3% Molybdenum adds significant strength to the material’s hardness & durability. In addition to this, the X90 has 0.07-1.2% Vanadium for added toughness, as well as shock / vibration resistance. Metallurgical differences to other materials are important to note, as the X46 contains these elements smaller quantities. Although the X46 does have similar properties to X90, they are not the same.

Read More about X46 Stainless Steel >> | Click here to enquire about linear shaft support rails >>

C60/C45 Hollow Linear Shafts (WH)

Some performance differences between these shafts and other steel bars occur during the manufacturing process. This process is know as Induction hardening, which involves induction heating, followed by quenching. This is shafts are heated and rapidly cooled down, resulting in the hardness of the linear shafts increasing. The brittleness does also increase during this process however, so subsequent operations are completed on the linear shafts.

Read More about C60 / C45 Hollow Linear Shafts >> | Click here to enquire about linear shaft support rails >>