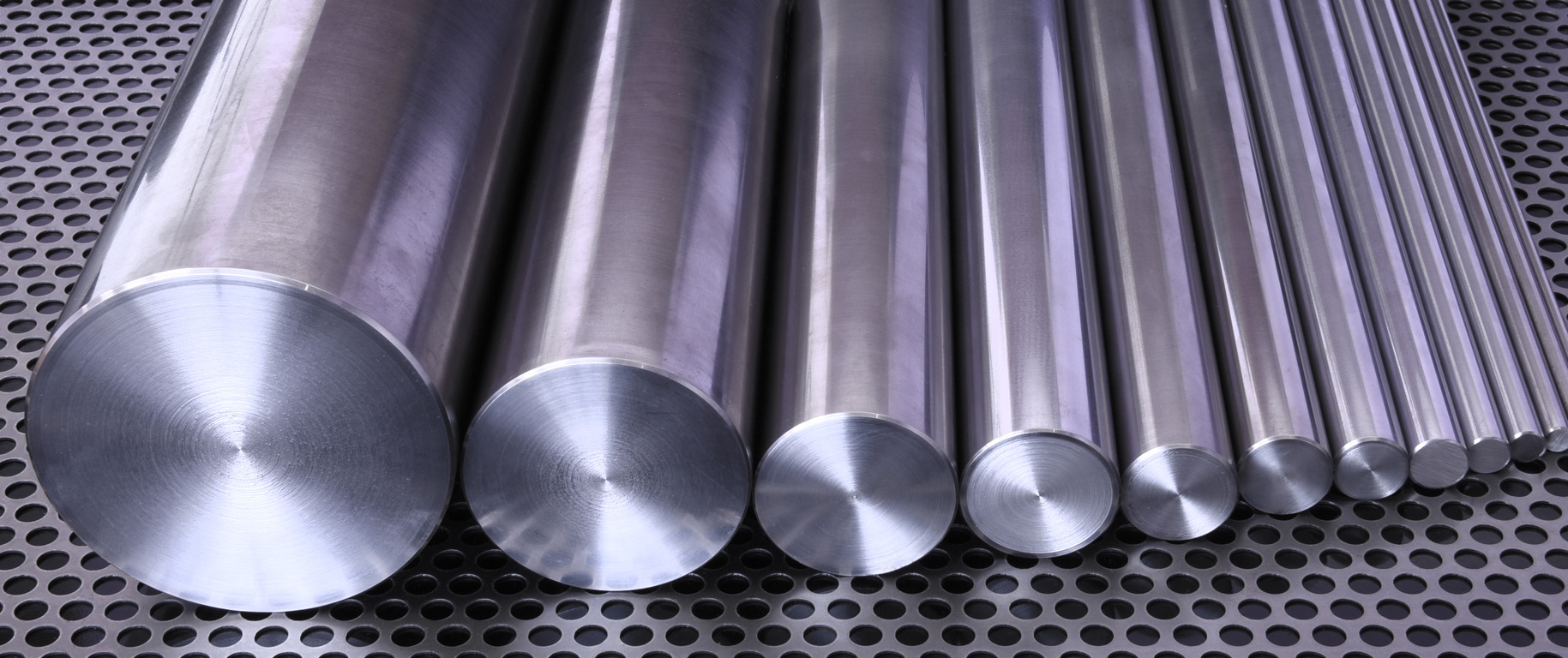

The X90 Stainless Steel Linear Shaft (WRA) is best used for applications where excellent resistance to corrosion is of paramount importance and the process these stainless shafts are subjected to during production ensures the prevention of excessive internal stresses.

Induction hardened linear shafts present a soft shaft core to ensure a good resilience and though at first glance, the X90 linear shaft may appear the same as any other linear shafts, the metallurgical differences are notable.

The X90 shafts contain 17-19% chromium content, which gives it the excellent corrosive resistance required, along with the 0.9-1.3% Molydbenum which helps the shaft’s strength, hardness and durability. As well as this, the addition of 0.07-1.2% Vanadium gives the material it’s toughness as well as shock and vibration resistant properties. It is due to these excellent hardening properties and high grinding finish that these shafts are selected to be used in high quality linear bearing and guideway systems in environments where corrosive resistant and induction hardened materials are paramount.

The process of induction hardening creates significant performance differences between linear shafts and steel bars. Induction Hardening is a form of thermal treatment where the linear shafts are firstly heated by a process called induction heating and then they are quenched – which involves rapidly cooling the material back down again. This process increases the hardness of the linear shafts but it also increases their brittleness, which means significant engineering experience is required when cutting the bar to break through it’s “induction hardened skin” as well as in subsequent machining operations e.g. keyways and planes, radial and axial drilling and tapping, milled flats and turned-down diameters.

The linear inner race requires the highest levels of taper and roundness, diameter, material cleanliness and straightness, surface hardening, surface finish and surface topography to provide optimal performance with minimal wear and maintenance. This is particularly important for the X90 linear shafts where a long life is often required for the application it serves and where any possibility of corrosion has to be negated to guarantee ultimate long-term performance.

There is no end to the applications for the linear shafts we supply

For any of your linear shaft or machining requirements, please email us or call us on +44 (0)1384 233397.

WRA

SWIPE RIGHT-LEFT TO VIEW MORE DATA

| Shaft Designation | Shaft Diameter d | Standard Length | Hardening depth Rht DIN 50190 | Standard tolerance ISO h6 | Roundness | Paralleism | Straightness | Weight |

|---|---|---|---|---|---|---|---|---|

| Type | mm | mm | mm | μm | μm t1 | μm t2 | mm/m t3 | Kg/m |

| WRA-5 | 5 | 2100 | 0.5 - 0.8 | 0 - 8 | 4 | 5 | 0.16 | 0.16 |

| WRA-6 | 6 | 3200 | 0.5 - 0.8 | 0 - 8 | 4 | 6 | 0.16 | 0.23 |

| WRA-8 | 8 | 6000 | 0.6 - 0.9 | 0 - 9 | 4 | 6 | 0.16 | 0.4 |

| WRA-10 | 10 | 6000 | 0.7 - 1.0 | 0 - 9 | 4 | 6 | 0.16 | 0.62 |

| WRA-12 | 12 | 6000 | 0.8 - 1.2 | 0 - 11 | 5 | 8 | 0.12 | 0.89 |

| WRA-14 | 14 | 6000 | 0.9 - 1.3 | 0 - 11 | 5 | 8 | 0.12 | 1.21 |

| WRA-15 | 15 | 6000 | 1.1 - 1.5 | 0 - 11 | 5 | 8 | 0.12 | 1.39 |

| WRA-16 | 16 | 6000 | 1.1 - 1.5 | 0 - 11 | 5 | 8 | 0.12 | 1.58 |

| WRA-20 | 20 | 6000 | 1.2 - 1.6 | 0 - 13 | 7 | 9 | 0.12 | 2.47 |

| WRA-25 | 25 | 6000 | 1.5 - 1.7 | 0 - 13 | 7 | 9 | 0.1 | 3.85 |

| WRA-30 | 30 | 6000 | 1.5 - 1.9 | 0 - 13 | 7 | 9 | 0.1 | 5.55 |

| WRA-40 | 40 | 3000 | 2.5 - 3.0 | 0 - 16 | 7 | 11 | 0.1 | 9.87 |

| WRA-50 | 50 | 3000 | 2.7 - 3.2 | 0 - 16 | 7 | 11 | 0.1 | 15.4 |

| WRA-60 | 60 | 3000 | 2.9 - 3.3 | 0 - 19 | 8 | 13 | 0.1 | 22.2 |

- Special tolerances and diameters are available upon request.

- Length tolerance: +200 / -0mm.

- Surface hardness: 55 HRC min.